Dyeing with Brown Onions, a great staple for eco dyeing.

I use onions a lot in my eco printing and dying. They are an easy and cheap way to get some great results. Today we will look at dyeing with brown onions.

Solar Dyeing

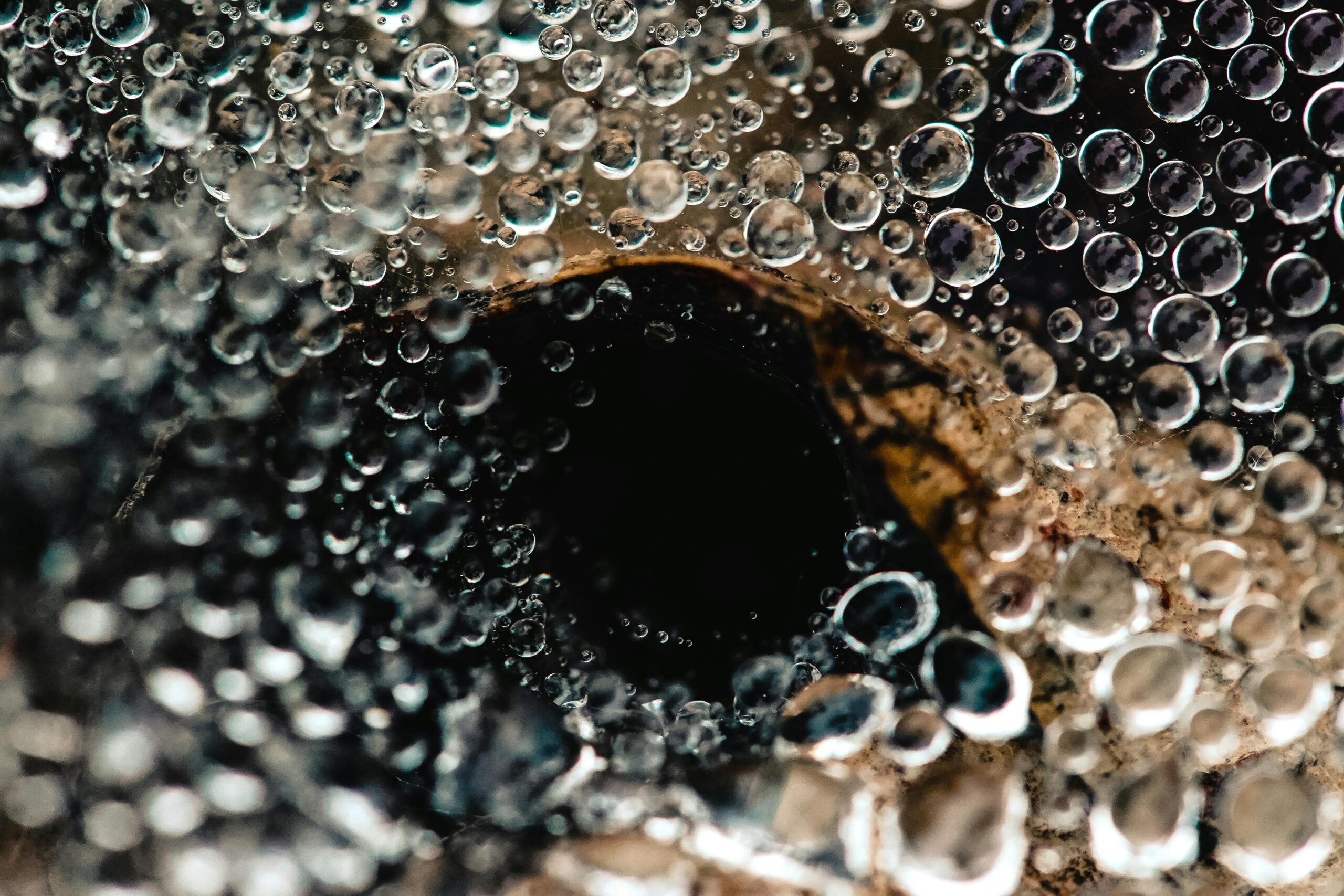

With this experiment, as with most , I am going to use the process of solar dyeing.

This is basically putting your dyestuff in a glass jar and leaving it in the sun to work its magic. The beauty of living in Australia means that I do have the benefit of hot summers. If you don’t have these conditions, it does not mean you cannot try this process. You will just need to experiment with your own environments advantages and disadvantages. Leave it in a room that gets sunlight and may have great heating or try longer dyeing periods.

These experiments are only to show you what has and hasn’t worked for me, so you can pick through the information to start your own experimenting journey.

Fibre Preparation

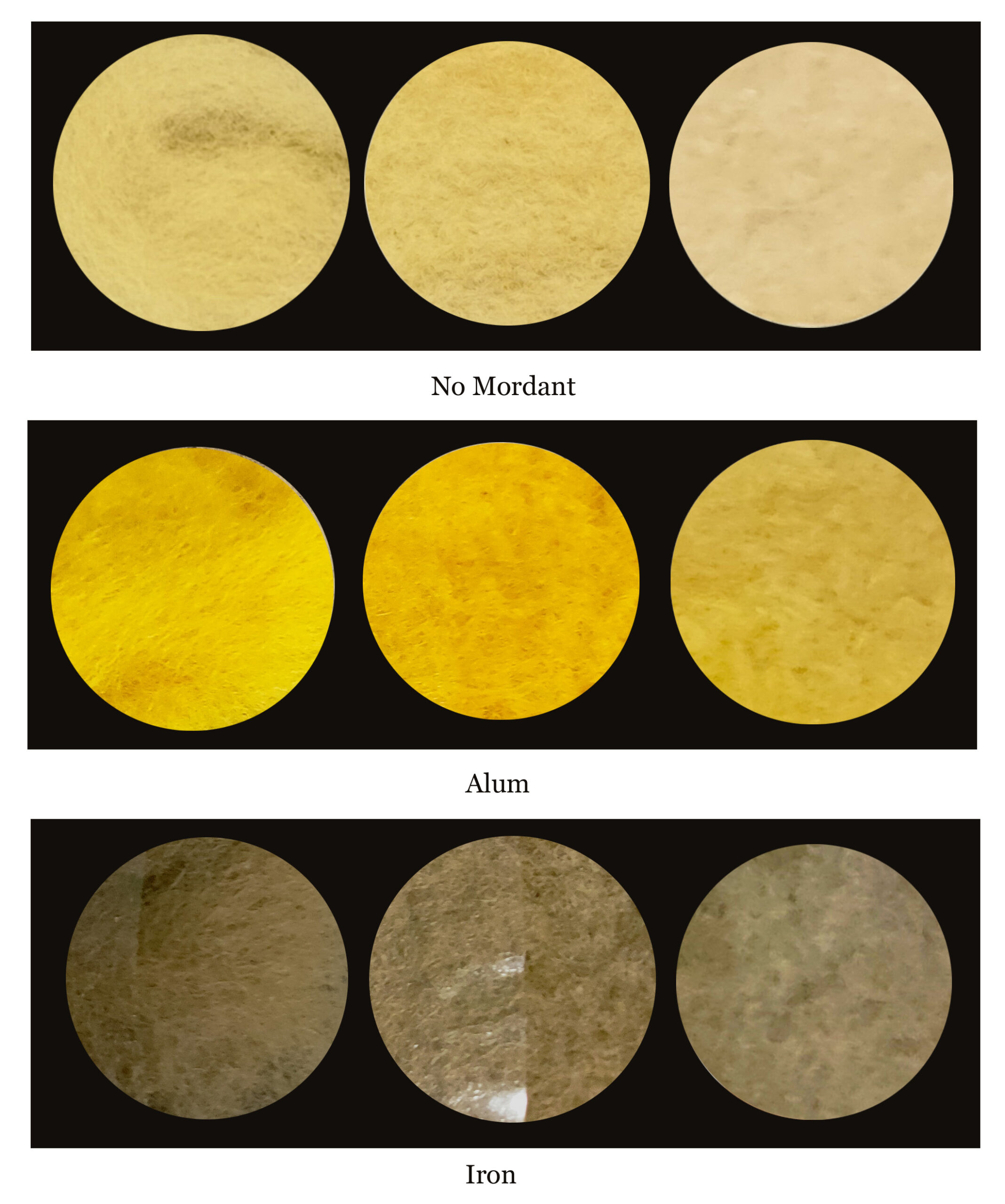

Before dyeing you must first scour and mordant your fibre. For this particular experiment, I used three different fibre preparations. One piece of roving was just scoured with no mordanting. For another I scoured and mordanted with alum and the other, I scoured and mordanted with iron. For information on these processes, try this post.

What you will need

Boiling water

Onion Skins- You just want the dry papery outside part of the skin.

Wool Fibre- I have used 10g of merino roving for each jar. Refer to fibre preparation as to the 3 types of roving used.

Glass Bowls

3 Glass Jars

Procedure for dyeing with brown onions

Step 1: Place your dyestuff in a heat proof bowl and add boiling water.

I divided my onion skins into 3 equal portions and placed into 3 separate bowls

Step2: When cool enough, transfer into your 3 separate glass jars and leave outside. I left these for a week in the hot Australian summer sun.

Step 3: Sieve your dye and add your fibre. Leave outside in the sun for 1 week. (It was summer in Australia, so was quite warm)

To recap, I had 1 jar with non mordanted roving in. 1 jar with alum mordanted roving and 1 with iron mordanted roving. All roving was scoured before mordanting.

Step 4: Take your wool out of the jar and leave to dry completely without rinsing.

Step 5: Rinse in water baths until they are clear. As I was using roving I did not want to use running water to start it felting, so I used a few bowls of water. Always make sure you wool does not experience dramatic temperature changes. Make your water room temperature. Leave to dry

Results of dyeing with brown onions

As you can see we can really get some nice vibrant colours from the plain old brown onion.

Across the page we have the roving after it was rinsed. Below is the felt made from the roving. I figured that the wet felting procedure would be a good indication of how well the dye stands up to washing. Then comes the sun test. The felt was left on a window sill for 4 weeks in the hot Australian summer to see if it would fade. (sun test on white background)

The non mordanted roving did deteriorate quite a bit in the sun and I really haven’t done anything with non mordanted onion dyeing since. The alum did deteriorate a little though no way near as much as the non mordanted. I am still experimenting with different techniques to try and stabilize this a little more, though unless you wanted something to sustain full sun a lot of the time, I still think this was a great dye and colour choice for your projects. The Iron mordanted felt really had very little deterioration. This photo is a little deceiving and in real life the difference is much less. It is a lovely light range brown that has a golden/ olive undertone, great for art and craft projects.

I hope this encourages to start your own journey with natural dyeing!! 🙂

Join us on Instagram www.instagram.com/DyetoCraft

Etsy Shop Now open

If you like the idea of using organic naturally dyed threads in your craft but just don’t have the time, come and have a look at our Etsy Shop where you will find an array of beautiful colours provided by nature.