Colour Differences when Natural Dyeing with Henna

Natural Dyeing with Henna has been done for centuries and is a great source of colour in your natural dye palette.

Solar Dyeing

With this experiment, as with most , I am going to use the process of solar dyeing.

This is basically putting your dyestuff in a glass jar and leaving it in the sun to work its magic. The beauty of living in Australia means that I do have the benefit of hot summers. If you don’t have these conditions, it does not mean you cannot try this process. You will just need to experiment with your own environments advantages and disadvantages. Leave it in a room that gets sunlight and may have great heating or try longer dyeing periods.

These experiments are only to show you what has and hasn’t worked for me, so you can pick through the information to start your own experimenting journey.

Fibre Preparation

Before dyeing you must first scour and mordant your fibre. For information on these processes, try this post.

Safety Note

Always ensure when dyeing of any nature, to keep all saucepans and utensils used in the process, separate from your general cooking supplies. You do not want to cook with anything that has been used to mordant or naturally dye your fibres. You should also wear gloves and a mask while handling your chemicals.

Measurements.

The first thing you will need to do before dyeing with Henna is weigh your fibre. You will need to know how much fibre you have, to determine how much Henna to use in your bath. This measurement is called WOF (weight of fibre). You should always weigh you fibres when dry and free from debris.

For this experiment I used 20% of WOF. So for 10g of wool roving I used 2g of Henna.

What you will need for dyeing with Henna

Boiling water

Henna- As I do not live in a country where it is easy to get the Henna plant material, I use a natural powder that comes from a natural dye shop.

Wool Fibre- Wool roving in 10 g lots. 1 mordanted with alum and 1 with iron and 1 with copper. See fibre preparation for these processes.

Cotton- I also ran some tests on some small swatches of cotton fabric which was scoured and mordanted with alum. See fibre preparation for these processes.

Iron Water (for cotton colour adjusting) You can easily skip this step. If you like to know how to produce iron water click here.

Glass Jars -For this experiment I used 4 jars. 1 for alum mordanted wool roving, 1 for iron mordanted wool roving, 1 for copper mordanted wool roving and 1 for 2 small swatches of cotton. Each jar was set up as a separate experiment with individual WOF’s and amounts of henna calculated.

4 bowls

Procedure

Step 1:

Place your henna into a bowl and cover with boiling water.

Step2:

When cool enough, transfer into your glass jar and leave outside for a day.

Step 3:

Sieve your dye and add your wet fibre. Leave outside in the sun for 1 week. (It was summer in Australia, so was quite warm)

Step 4:

Take your wool and or cotton out of the jar and leave to dry completely without rinsing.

Step 5:

Rinse in water baths until they are clear. With the roving I did not want to use running water to start it felting, so I used a few bowls of water. Always make sure you wool does not experience dramatic temperature changes. Make your water room temperature. Leave to dry.

You do not have to be so carful with the cotton, Give it a good rinse in hot water until the water runs clear.

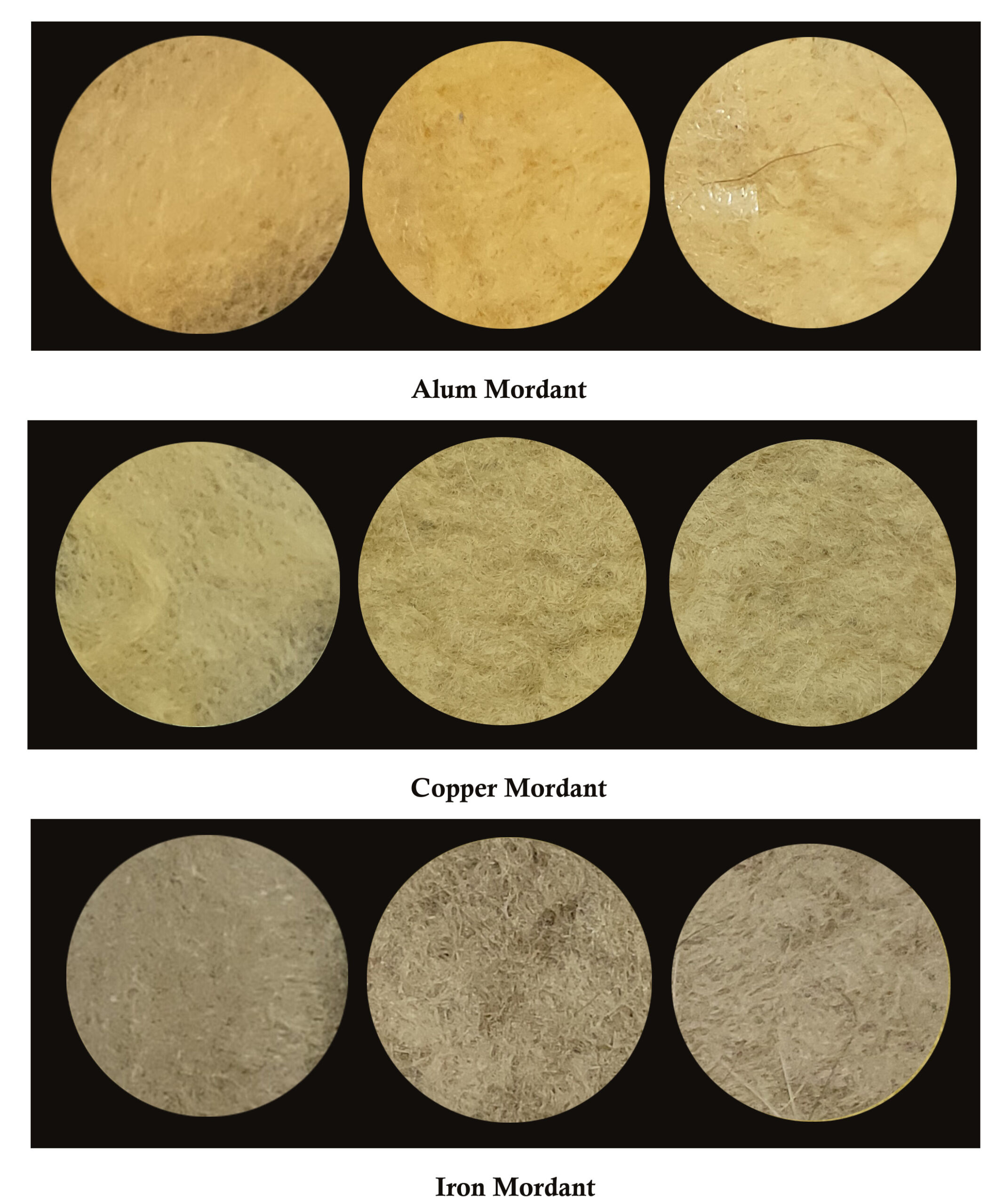

Results of dyeing with Henna on Wool

The first circle in each row shows the roving when rinsed and dried. The next circle is after the roving was wet felted using a gentle olive oil soap. And the third circle is the felt after it has spent 4 weeks in the sun.

As you can see from the picture I achieved some great results. The alum mordanted wool did fade a little but the copper and iron held up to the sun tests quite well. I was so happy with these results I decided to have a go at dyeing with some 2ply merino wool thread.

The next picture shows these results. The threads on the left are mordanted with copper while those on the right are mordanted with iron. The second row of threads is after 1 week of hot aussie sun.

The copper mordanted thread came out more of a golden colour than the roving which had a greener tinge. The threads did not fade at all with one week in the sun which was great news.

I then used the threads to embroider a few lines and gave them a good wash. There was no running of colour or fading. YAY

Results of dyeing with Henna on Cotton

So these are the swatches of cotton that were dyed. I had dyed 2 swatches in the dye bath. One of the swatches was then put into some iron water for 40 sec. It was rinsed both before and immediately after the iron dip. And these are the results

The first line is the henna both before and after a 4 week sun test. There was a little fading which is more common with cotton but I was still quite happy.

The second line was after the iron dip. Again there was some fading but I was still very happy with the colour achieved.

I hope this helps and encourages you to try your own experimenting in the world of natural dyes. 🙂

Join us on Instagram www.instagram.com/DyetoCraft

Etsy Shop Now open

If you like the idea of using organic naturally dyed threads in your craft but just don’t have the time, come and have a look at our Etsy Shop where you will find an array of beautiful colours provided by nature.