Dyeing with Lac- Solar versus Heat methods when natural dyeing

Dyeing with Lac can produce some beautiful pinks and purples, but what is the best method to dye with?

In this post I am actually going to be dyeing with an extract that was bought from a natural dye supplier rather than from something in my immediate environment. There are a few colours which unfortunately are a little hard to get from my local area so it was time to start looking at bought natural dyes to help expand the colour palette.

Lac is a dye source that comes mainly from Asia. It is actually a resin that is produced by the Kerrie lacca bug so if you are vegetarian, this may not be the dye for you. It is also the same source for shellac which has many uses such as furniture polish, food coatings and even used in the cosmetic industry.

Dyeing with Lac

In this experiment I will be doing 2 different methods of dyeing. I always prefer solar dyeing if I can. It is a much slower method of natural dyeing but does reduce the need for electricity and therefore a little better for the environment.

I will however also do some heat dyeing to look at what sort of differences can be achieved. As usual I will do both wash and sun tests on the dyed fibre.

These experiments are only to show you what has and hasn’t worked for me, so you can pick through the information to start your own experimenting journey.

Safety Note

Always ensure when dyeing of any nature, to keep all saucepans and utensils used in the process, separate from your general cooking supplies. You do not want to cook with anything that has been used to mordant or naturally dye your fibres. You should also wear gloves and a mask while handling your chemicals.

Fibre Preparation

Before dyeing you must first scour (wash) and mordant your fibre.

For this experiment I have used wool roving mordanted with alum, iron and copper.

What you will need when solar dyeing with Lac

Water

Lac extract

Wool Fibre-I used 4 lots of 10g of merino roving for each experiment. 1 was scoured with no mordant, 1 was mordanted with alum, 1 with iron and 1 with copper.

4 Glass Jars

4 bowls

measuring scales

Measurements.

The first thing you will need to do is weigh your fibre. You will need to know how much fibre you have, to determine how much lac to use in your solution. This measurement is called WOF (weight of fibre). You should always weigh you fibres when dry and free from debris.

For this experiment I decided to use 10% of WOF. So for 10g of wool roving I used 1g of lac extract.

Procedure

Step1: Place 1g of lac extract into each bowl. (refer to measurement section and adjust if using something other than 10g of fibre). Add boiling water to each bowl.

Step2: When cool enough transfer each bowl into a glass jar and leave for 1 day.

Step 3: Add your fibre into each jar. So I had 1 jar with non mordanted roving, 1 with alum mordanted roving, 1 with iron mordanted roving and 1 with copper mordanted roving. Leave for 1 week in full sun.

Step 4: Take your wool out of the jar and leave to dry completely without rinsing.

Step 5: Rinse in water baths until they are clear. As I was using roving I did not want to use running water to start it felting, so I used a few bowls of water. Always make sure you wool does not experience dramatic temperature changes. Make your water room temperature. Leave to dry

Results from Solar Dyeing with Lac

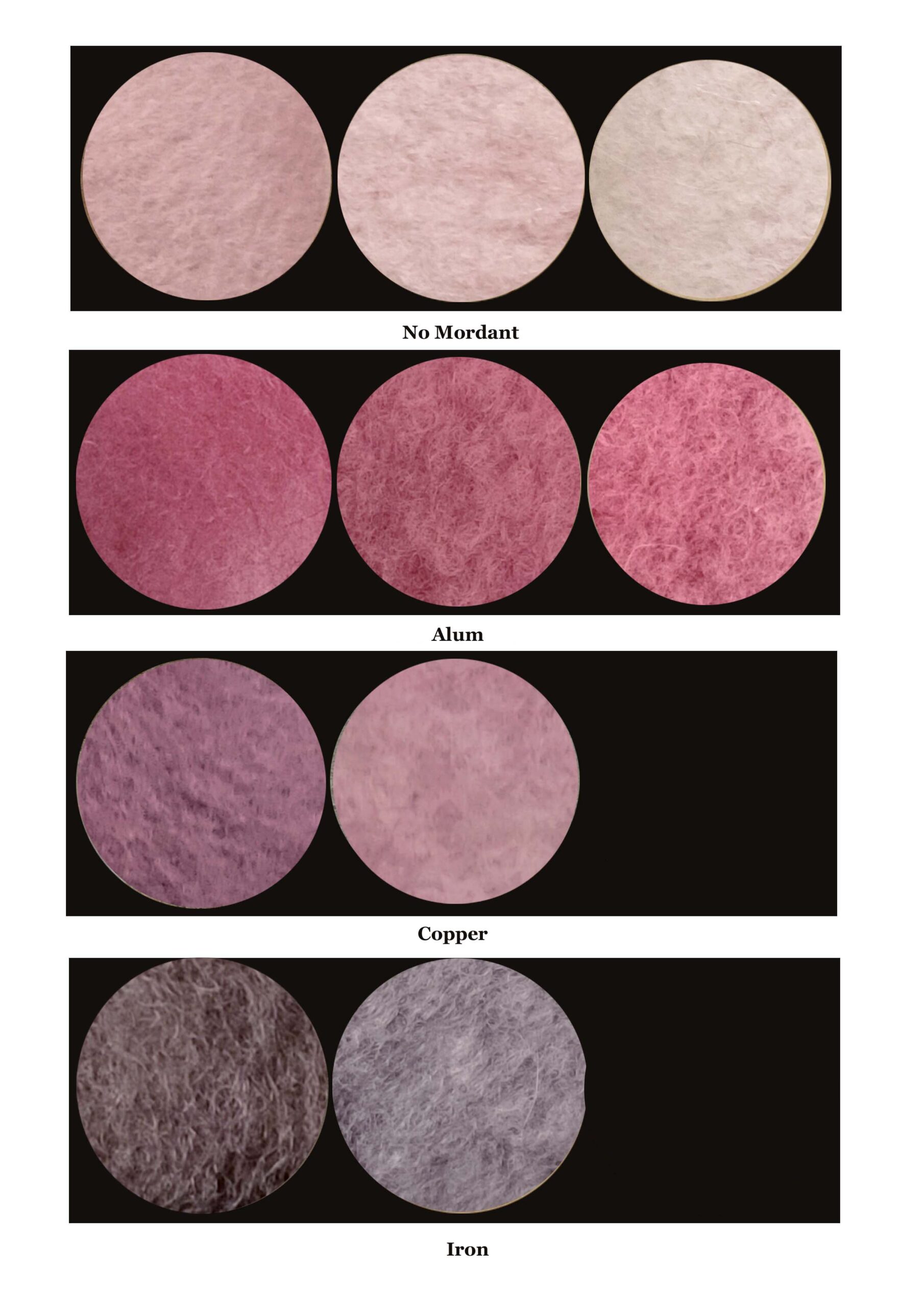

Lac does produce some beautiful vibrant colours. In this result panel we have merino wool first scoured but not mordanted. The next line shows wool with alum mordant. Then is the copper mordant and finally the iron.

Across the page we have the roving after it was rinsed. Then comes the felt made from the roving. I figured that the wet felting procedure would be a good indication of how well the dye stands up to washing. Then comes the sun test. The felt was left on a window sill for 4 weeks in the hot Australian summer to see if it would fade.

As you can see there was definitely fading in the felting process. To the point where I didn’t even continue with the sun test for the copper and iron felt. Although these were beautiful colours I felt that maybe we could do better with the durability of the dye as it is not known to be a fugitive dye. So it was time to try some heat dyeing.

What you will need when heat dyeing with Lac

Water

Lac extract- refer to measurement as for solar dyeing

Wool Fibre-I used 10g of merino roving that was mordanted with alum

Saucepan

heat source

measuring scales

thermometer

Procedure

Step1: Place 1g of lac extract into saucepan and dissolve with hot tap water. (refer to measurement section and adjust if using something other than 10g of fibre). Add enough water to the saucepan that the fibre can move freely.

Step2: Add your wool and simmer for 45minutes. The temperature should be around 75 degrees celsius.

Step 3: Turn heat off and leave wool in saucepan overnight

Step 4: Take your wool out of the saucepan and leave to dry completely without rinsing.

Step 5: Rinse in water baths until they are clear. As I was using roving I did not want to use running water to start it felting, so I used a few bowls of water. Always make sure you wool does not experience dramatic temperature changes. Make your water room temperature. Leave to dry

Results from Heat Dyeing with Lac

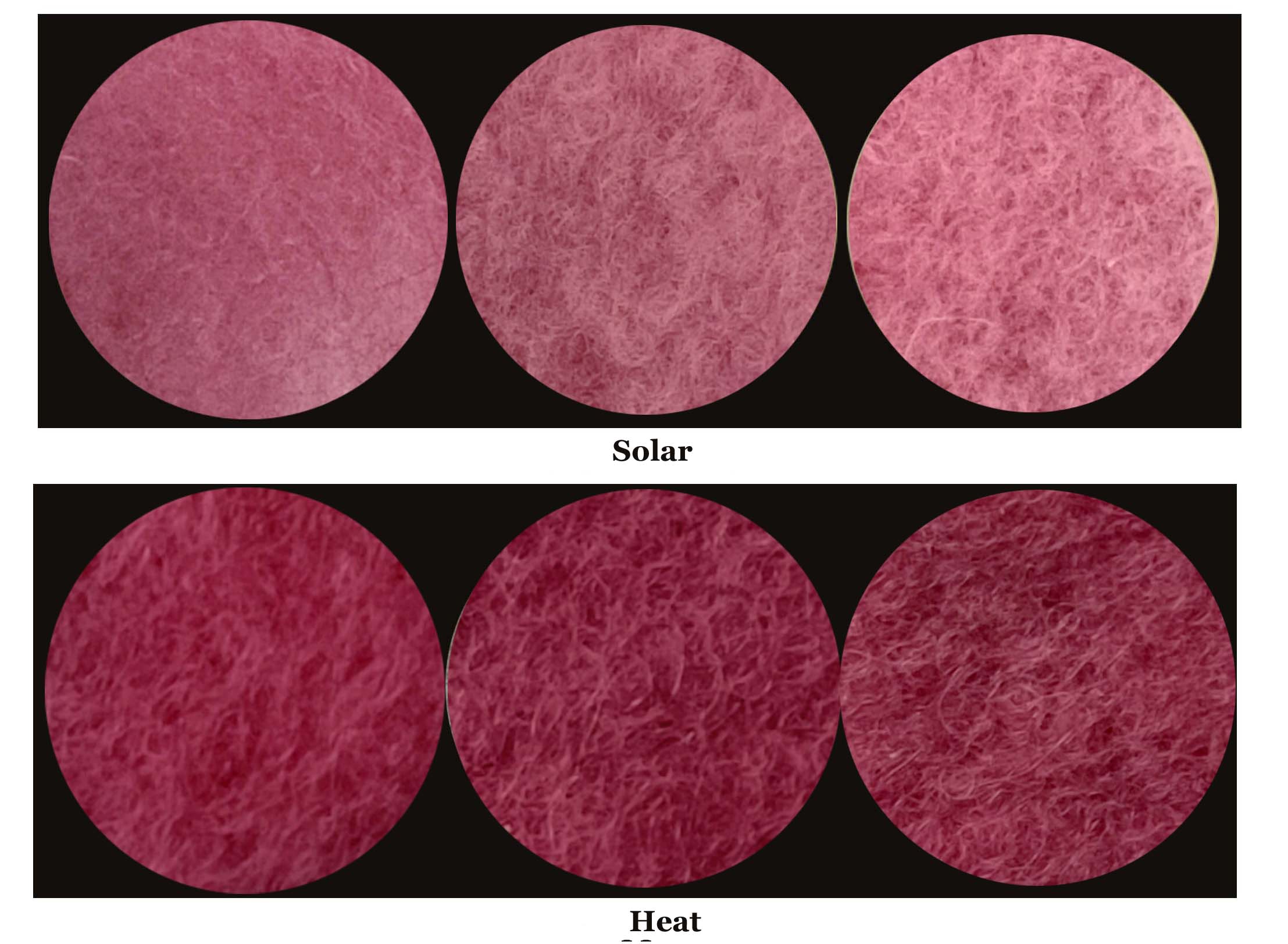

Well heat has definiately made a difference in this case. The top line shows the results from the solar dye while the 2nd shows the results from the heat.

Across the page we have the roving after it was rinsed. Then comes the felt made from the roving. The felt was then left on a window sill for 4 weeks in the hot Australian summer to see if it would fade.

As you can see the heat dyed sample did not fade with either felting or sun test. It remained a strong pure colour that was vibrant and vivid no matter what happened to it.

I hope this helps and encourages you to try your own experimenting in the world of natural dyes. See what colours the bark around your own backyard might produce 🙂

Update 6/9/2024

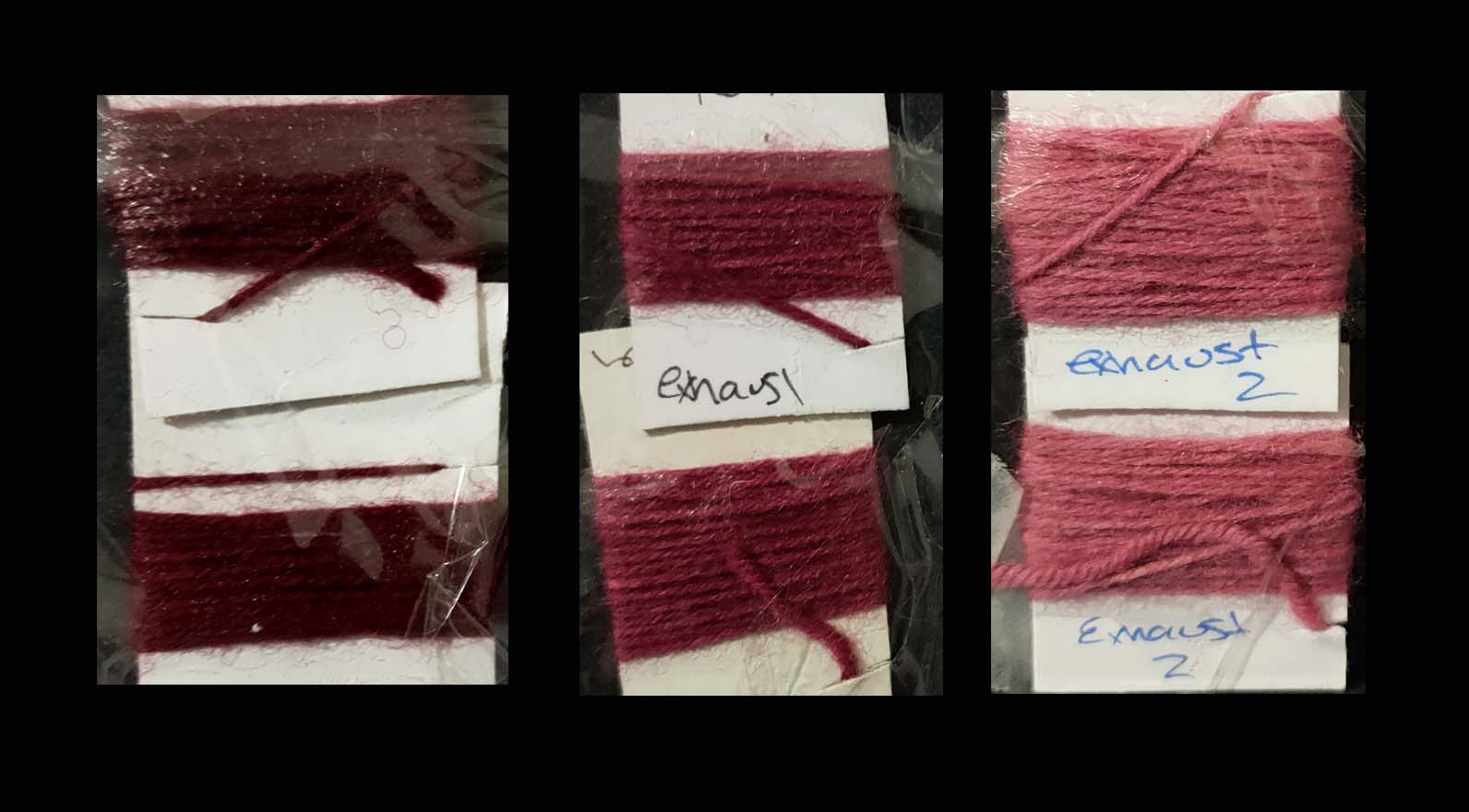

Since the first lot of experiments with lac I have used it quite a bit. It is a great dye that can be manipulated and changed for some great results. In these incidents I used lac on alum mordanted wool threads. These are the results from the initial dye bath and then 2 exhausts. I managed to actually get 6 dye lots out of the one bath giving me a great range of shade.

The top picture shows the threads both before and after 1 week in the full sun. As you can see there has been no fading at all.

The second picture shows the threads used in chain and split stitch. The first square is after the threads have been squirted with water to check that the colour would not run . The 2nd square shows the threads after a hand wash with gentle soap. They have then been dried. Again no running!! . I was actually a bit surprised. I did expect some running as I can quite often have trouble with commercial threads in the red range. It was great to get these results.

Join us on Instagram www.instagram.com/DyetoCraft

Etsy Shop Now open

If you like the idea of using organic naturally dyed threads in your craft but just don’t have the time, come and have a look at our Etsy Shop where you will find an array of beautiful colours provided by nature.