Dyeing with dried Black Beans and getting a great variety of colour.

While dyeing with dried black beans we will look at a different type of process for dyeing.

Dyeing Technique

With this experiment, we will not be using the solar dyeing method. The sun and heat can damage the dye produced by the black beans.

Instead the beans will be kept in a dark, cool place to soak, so this dye process can easily be done if you live in a cold part of the world!

We will also be soaking our finished dyed wools, in some different baths to see how pH can change colours with certain dyestuff.

Fibre Preparation

Before dyeing you must first scour and mordant your fibre. For information on these processes try this post.

What you will need to dye with dried Black Beans

Water

Dried Black Beans- I used a kilo bag in this experiment which was probably way more than I needed.

Wool Fibre- In this instance I used 30g of merino wool roving split into 3 10g lots. It was pre mordanted with alum, following the procedure shown in a previous blog. (click on the getting started button above.)

Plastic container-large enough to fit your beans in after they swell up with water

2 large bowls

Black beans

Baking Soda

Vinegar

Procedure

Step 1: Place black beans into your plastic container and cover in water.

Step 2: Leave in a cool dark place for a few days to soak. Keep checking on your beans and add water to keep them covered. They will soak up the water and increase in size so you need to keep adding water.

Step 3: After about 3 days strain the beans out of the coloured water, and add your mordanted, wet wool.

Step 4: After 4 or 5 days, make baths up using your bowls. In 1, place water and a large dash of vinegar. In the other use a teaspoon of baking soda into water. You may need to dissolve the baking soda into a small amount of hot tap water first. If you are dyeing wool , make sure your baths are a similar temperature to the water the wool is coming out of. You do not want to have a large temperature change, as you will start felting the wool.

Step 5: Place 1 of the 3 lots of fibre into the baking soda bath and 1 into the vinegar bath. Leave to soak for up to an hour. I found that the wool in the baking soda bath, changed colour quickly, while the vinegar bath took awhile.

Step 6: Rinse and dry.

Results for dyeing with dried Black Beans

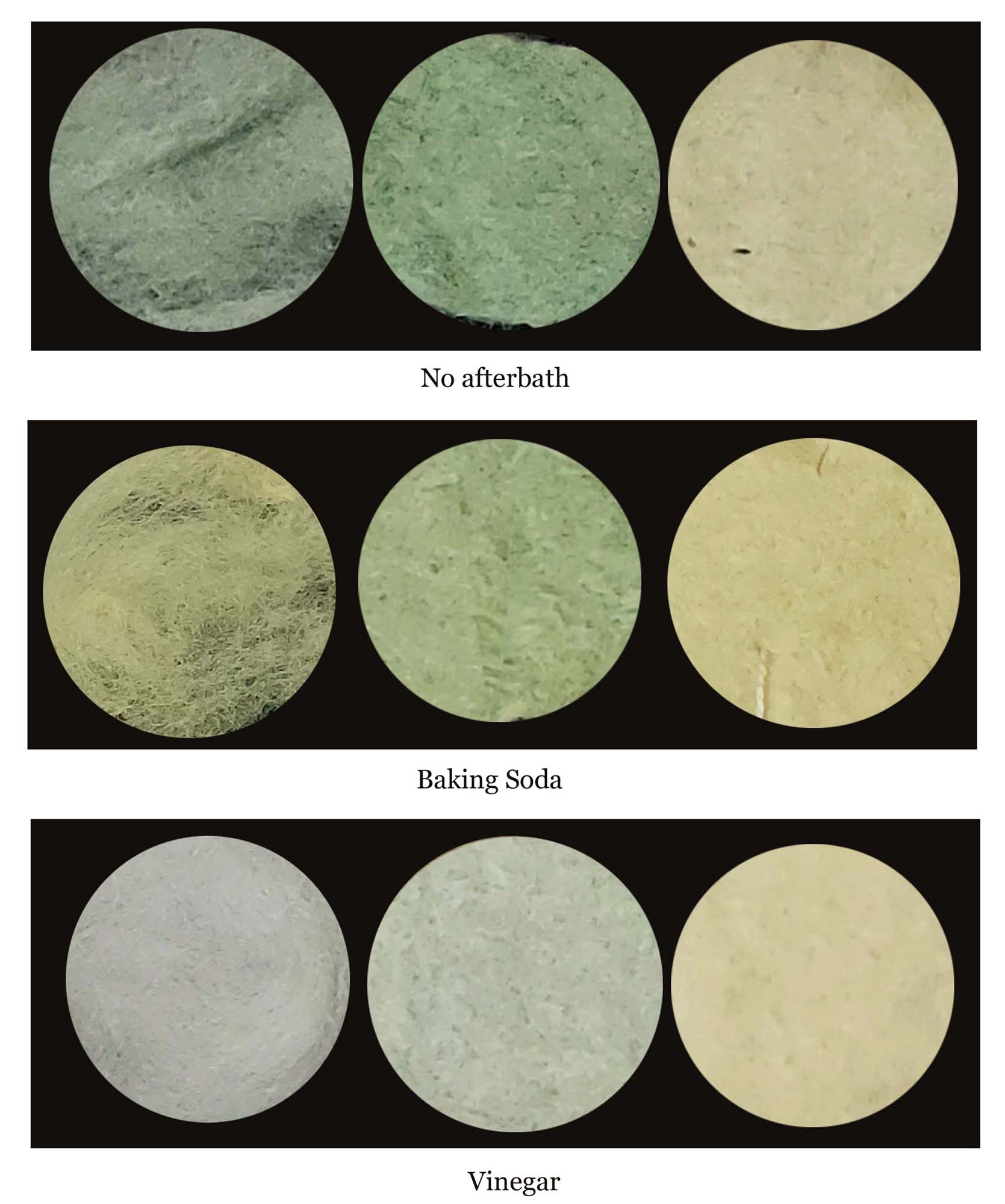

As you can see we have a nice variety of colour from the different baths. The top 3 are from the black beans with no after bath. The 2nd row is after a baking soda bath, while the 3rd is after a vinegar bath. The bottom colour looks a little washed out in this picture. In real life it is a little more blue.

Across the page we have the roving after it was rinsed. Then comes the felt made from the roving. I figured that the wet felting procedure would be a good indication of how well the dye stands up to washing. (I did add a little vinegar into the water when felting the vinegar bath roving, to try and keep the ph consistent.) Then comes the sun test. The felt was left on a window sill for 4 weeks in the hot Australian summer to see if it would fade.

While felting, the colour did seem to stand up to washing with a gentle soap (like olive oil or goats milk). The sun test , however, totally wiped the colour away.

Although it was disappointing that the colour faded in the sun test, it was not unexpected. It is well known that black bean dye is a fugitive dye. I was surprised that it held up to the felting so well. These are colours that I will definitely use in the future, just not on anything that will be near sunlight.

I hope this helps and encourages you to try your own experimenting in the world of natural dyes. 🙂

Join us on Instagram www.instagram.com/DyetoCraft

Etsy Shop Now open

If you like the idea of using organic naturally dyed threads in your craft but just don’t have the time, come and have a look at our Etsy Shop where you will find an array of beautiful colours provided by nature.