Mordanting with Alum to get ready for natural dyeing

Today we are talking about mordanting with alum. We will look at what mordanting is and how it helps with natural dyeing.

Mordanting with alum

Mordanting is the second stage of dyeing techniques used in the natural dyeing process.

It is the process of preparing your fibers to receive the plant material on a chemical level and usually involves the use of a metal compound which helps the dye adhere and stay onto the fibre. It also helps to stabilize the dye so that it has less chance of fading through sunlight or washing.

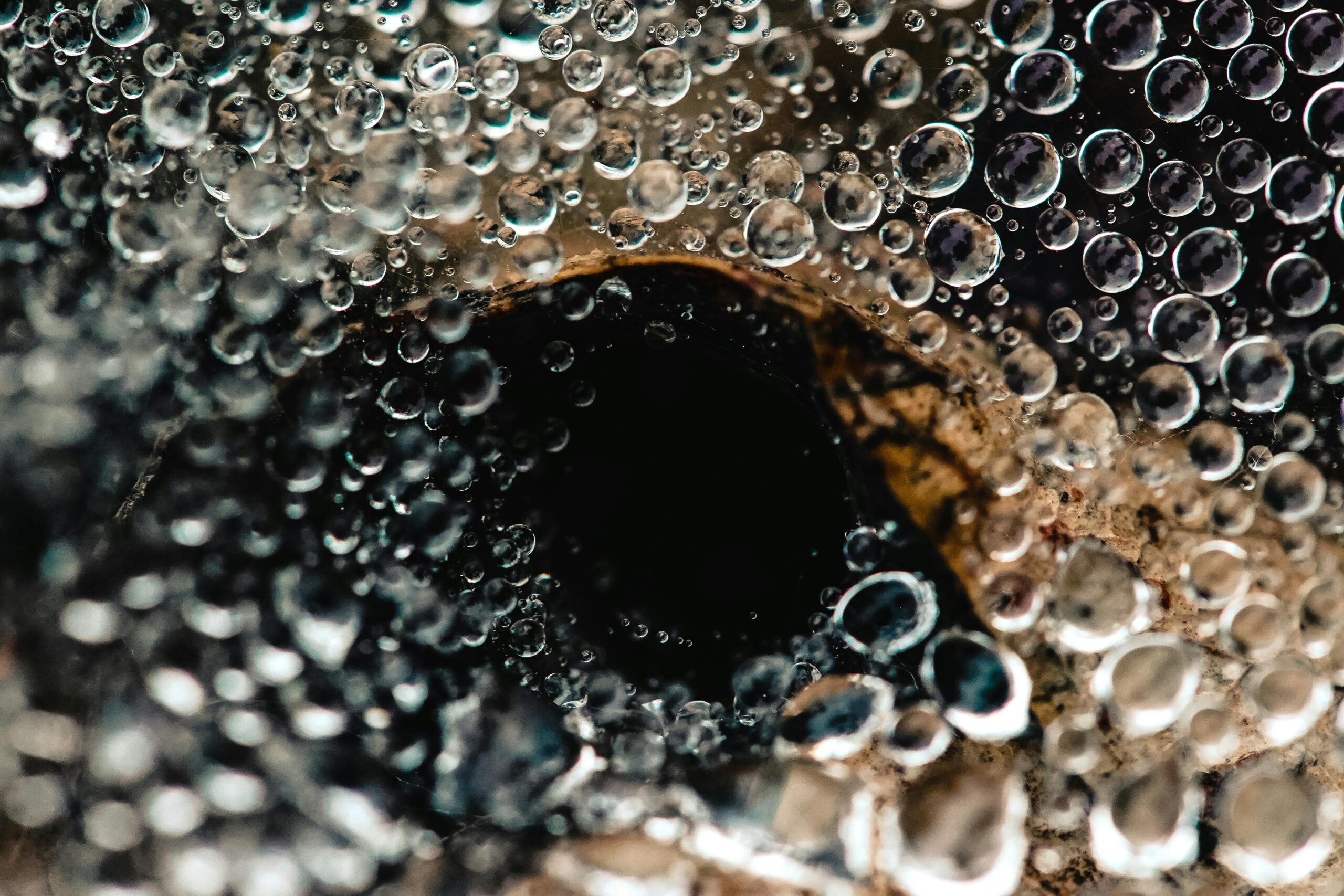

Mordanting works differently on cellulose and protein fibres. It may not even be needed for some natural dyes. It really all depends on the chemical reactions between the natural dye material and the fibre, as well as the way the actual dye stuff adheres to the fabric. For example with some dye stuff like indigo, the dye does not actually adhere to the fiber but attaches itself to the air bubbles surrounding the fibre and then expands to the point where it gets trapped, giving the appearance that the material has been dyed.

In this post we are looking at how to mordant protein fibres with an alum mordant. There are a large variety of mordants available for natural dyeing. Not only metal compounds but also more natural mordants like soy milk. Some of the other mordanting posts on this web site are :

We will be looking at Cellulose fibres in the near future.

The most typical mordant that is used for protein fibres is alum. It is Potassium Aluminium Sulphate and is quite readily available from most stores that supply dyeing products. It is also the less toxic of the metals used in the mordanting process so is a great way to begin mordanting.

Safety Note

Always ensure when dyeing of any nature, to keep all saucepans and utensils used in the process, separate from your general cooking supplies. You do not want to cook with anything that has been used to mordant or naturally dye your fibres. You should also wear gloves and a mask while handling your chemicals.

Washing your fibre is the first stage of your fibre preparation. The technical term is scouring and is slightly different depending on whether you are going to dye protein or cellulose fibres.

If you are unsure whether your cotton, wool, linen or any other type of fabric, is classified as protein or cellulose, click on the Fibre Type button.

If you are unsure of the washing process of your protein fibres click the Wash button below.

What will you need for mordanting with alum?

Saucepan- large enough that your fibres can move gently through the water

Water

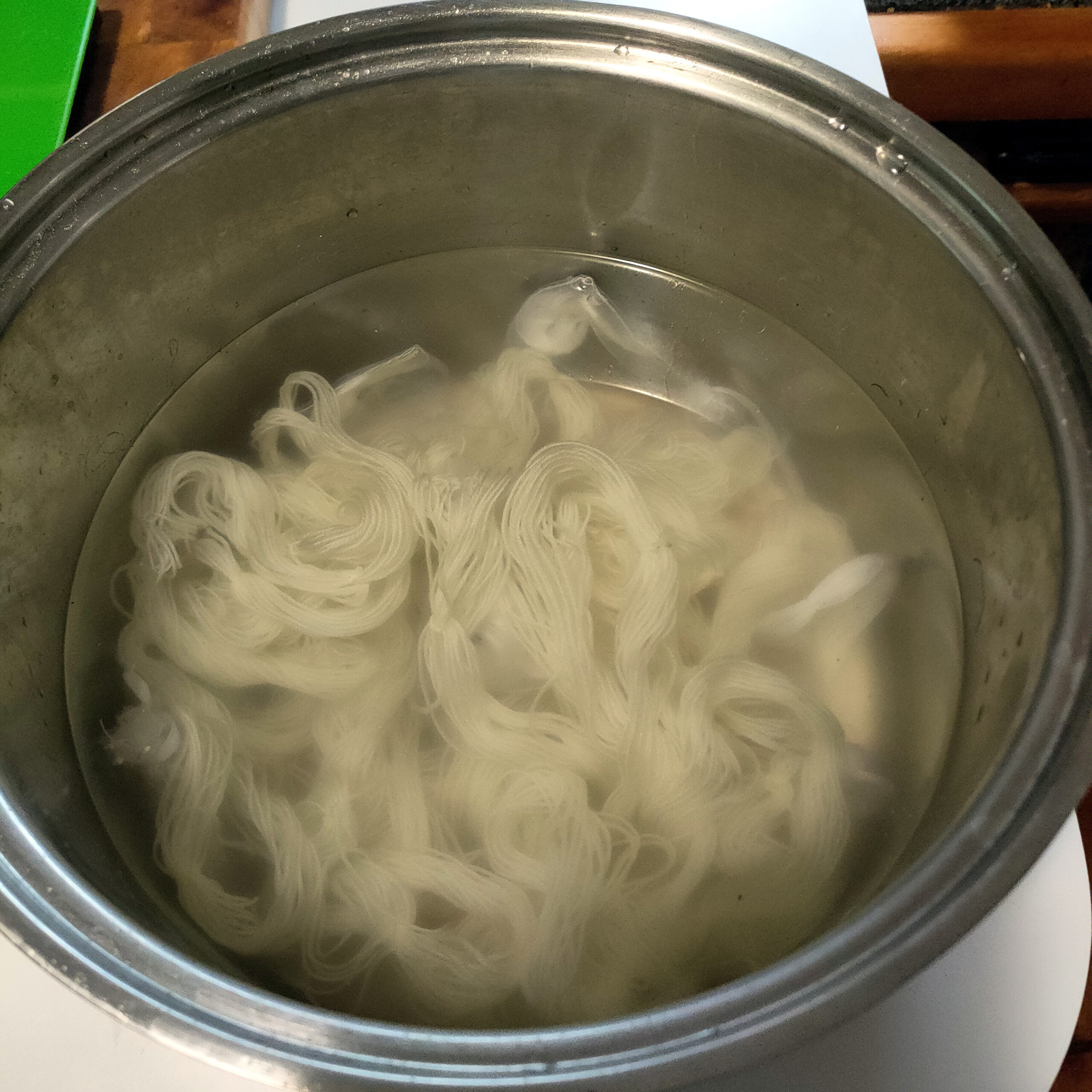

Washed Fibre- Your fibre should be wet when added to the pan. You can mordant your fibre straight after washing and rinsing. If you have previously dried your fibre after washing, place it in a bowl of water for half an hour to get the cells open and ready for the mordanting with alum.

Alum Mordant

Cream of Tartar

Cooking Thermometer

Scales

Measurements.

The first thing you will need to do is weigh your fibre. You will need to know how much fibre you have, to determine how much alum and cream of tartar to use in your solution. This measurement is called WOF (weight of fibre). You should always weigh you fibres when dry and free from debris.

In most instances I use 10% WOF of alum and 7% WOF of cream of tartar. Different recipes can use different amounts of alum. but unless otherwise stated, you can safely assume I have mordanted my fibres with 10%. I would not recommend going above 15% of alum, as it may deteriorate you fibres in the long run.

So if you have 100g of fibre, you will need 10g of alum and 7g of cream of tartar.

Weigh these out and dissolve them in hot tap water first.

Process of mordanting with alum.

Step 1:

Place enough water in your saucepan so your fibres can move freely. The water needs to be able to easily move around and through your fabric/fibre to fully get the chemicals to penetrate.

Step2:

After weighing our fabric / fibre and calculating how much Alum and Cream of Tartar you need, dissolve them in a glass of hot tap water. You need to give them a good stir to get all of the granules dissolved. Add your dissolved chemicals into the water and stir.

Step3:

Gently add your wet fibres and submerge them under the water. You may need to gently squeeze your fibre to release air bubbles. Any air traps in the fibre will block the mordant from attaching to it. While doing this, be as gently as possible if you are mordanting wool. You do not want to agitate the wool too much as it may cause it to felt. Take your pot to the stove. Place a thermometer into the pan.

Step 4:

Turn your stove top on and allow the water to get to 80 degrees Celsius (176 Fahrenheit).

Step 5:

Leave your fibre for 40 min at 80 degrees. Do not allow your water to boil! If you are mordanting wool it will start felting when in boiling water.

Step 6:

Turn your heat off and leave the pan on the stove top to cool down. You want your fibre to cool down gradually.

I normally leave the fibre in the saucepan overnight for a bit of extra time in the mordant. You can however take it out as soon as it has cooled down to begin the dyeing process.

You can now move on to dyeing your fibre or let it dry before putting it away for future use. If you do let it dry for later, make sure to let it stand in some water again before dyeing. Your fibres will attract the dye much easier if they are wet.

I always try to mordant as big a batch of fibre as my saucepan will comfortably fit. you can then hang it out to dry and re wet when you are ready to dye. I find it much more economical and quicker to batch scour and mordant my fibres.

If you are re wetting your mordanted fibres for dyeing, leave them in the water for at least 15 minutes. This allows the cells in your fibre to open up and accept the natural dye much easier. As with the earlier processes, you will need to gently place the fibre in room temperature water and gently squeeze out any air bubbles. You do not want to agitate the wool too much as it may cause it to felt.

Join us on Instagram www.instagram.com/DyetoCraft

Etsy Shop Now open

If you like the idea of using organic naturally dyed threads in your craft but just don’t have the time, come and have a look at our Etsy Shop where you will find an array of beautiful colours provided by nature.